PVD (Physical Vapor Deposition)

DIE CASTING

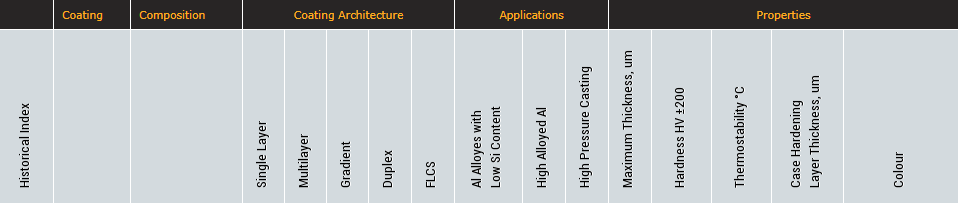

Common surface failures during cold work range from forming, stamping, fine blanking, punching to powder compacting. This can result in abrasive wear, adhesive wear or galling. Sputtek offers a variety of PVD coatings for cold work tooling to help extend the life of your tool. For your reference, we have provided the table below with a list of coatings for specific applications.

| 0 | CRN | CRN | + | + | + | 10 | 1800 | 800 | 50÷70 | Silver | |||||

| 0 | V10 | VCN | + | + | + | 10 | 2100 | 700 | 50÷70 | Yellow | |||||

| 0 | TiAlN | TiAlN | + | + | + | 8 | 3000 | 900 | 50÷70 | Dark Purple | |||||

| New | DC – 1 | CRTiAlN | + | + | + | + | + | + | 12 | 3000 | 900 | 50÷70 | Dark Purple | ||

| New | DC – 2 | CRTiSiN | + | + | + | + | + | + | 12 | 3500 | 1100 | 50÷70 | Dark Bronze | ||

| New | DC – 3 | VTiSiN | + | + | + | + | + | + | 12 | 3500 | 1100 | 50÷70 | Dark Bronze |

Agenda: * FLCS – Functional Layers Coating System