Machines

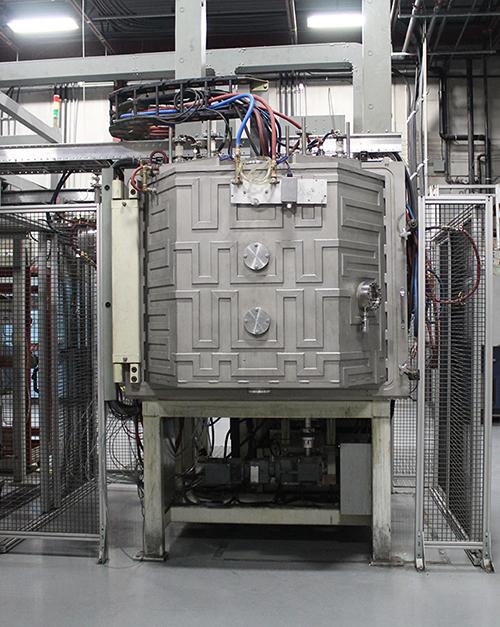

MODULAR DUPLEX UNIVERSAL SPUN 4

The plasma managing system of this PVD coating machine allows coating deposition in highly concentrated and ionized conditions. The result is the deposition of dense coatings with low internal stresses.

Description

Parameters

Chamber volume

4.6m³

Chamber Dimensions

3.2m L x 1.5m H x 1.7m D

Effective Coating Area

2 zones diameter 1m x 0.8m

Number of Doors / Sub Doors

2 Rotating table with 6 planetary tilted sub tables with adjustable angles (0 – 25 degree)

Table Diameter

1,000mm x 2

Maximum weight of the load per Table / Sub Table

2,500/350 lb

Maximum Load Per Machine

5,000 lb

Maximum part weight

2,000 lb

Maximum part height

700mm

Chamber / DoorMaterial

Stainless steel

Maximum vacuum level

10-5 torr

Vacuum recovery time

60 min form atmosphere to working vacuum degree

Heaters

Infrared heaters 60 KW evenly installed inside the chamber around each table

Process Temperature

150-650°C

Shields

2 sets

Gas Distribution System

6 flow meters

Cooling system

SS water chanels

Vacuum system

SS water chanels

Vacuum system

Mechanical pump, Booster Pump, 2 Turbo Pump (3,300 l/c)

Cathodic Arc Sources 180 mm diameter or circular, linear or cylindrical sputtering system replacing fully or partially cathodic arc sources

8-12

Rapid Plasma Heating System

1

Processes

Direct PVD, Ion Nitriding+PVD, PECVD, DLC, Hybrid Processes, Ion Stimulated Diffusion

Maximum power

250 KVA